BRÜGGEMANN / Steel construction

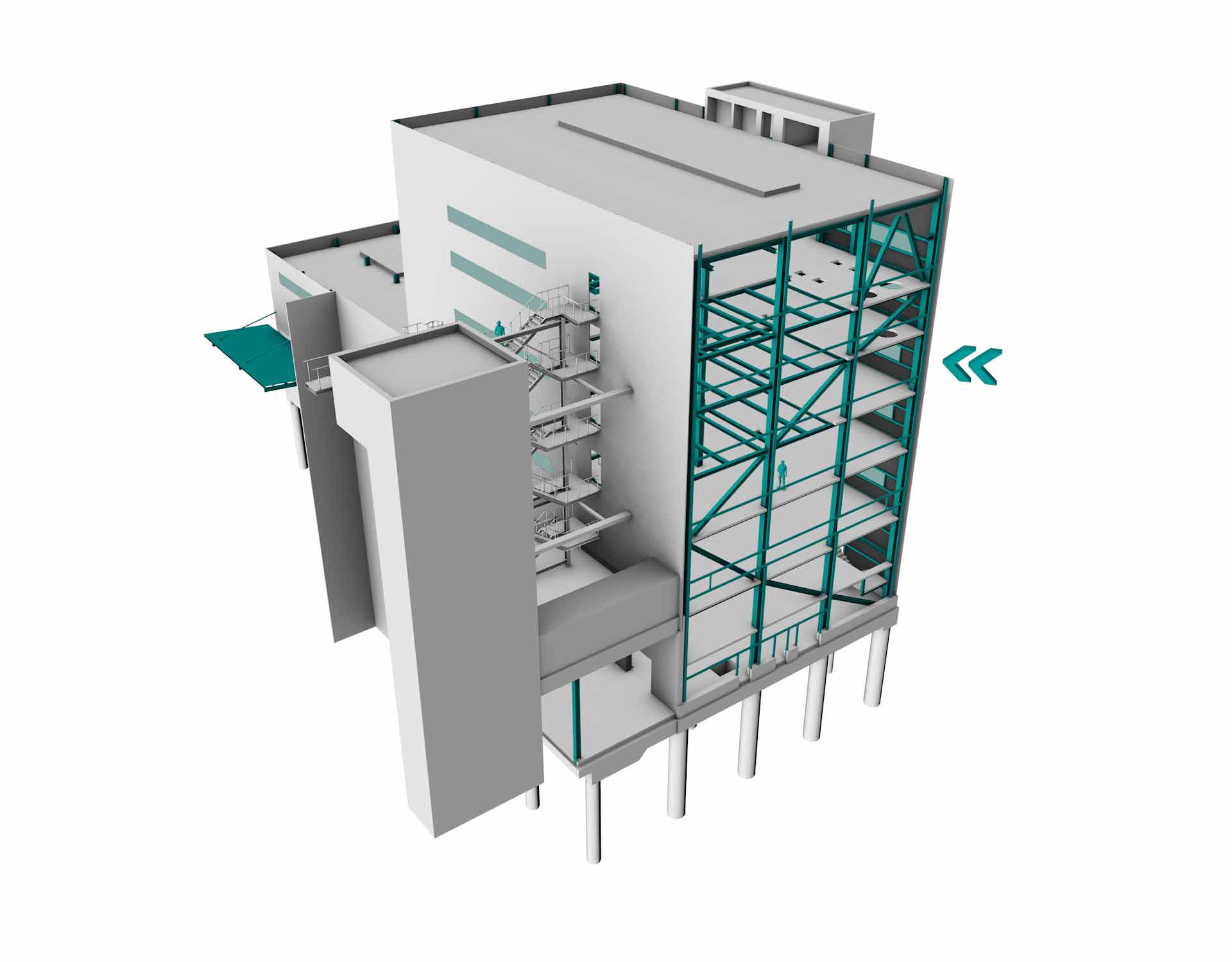

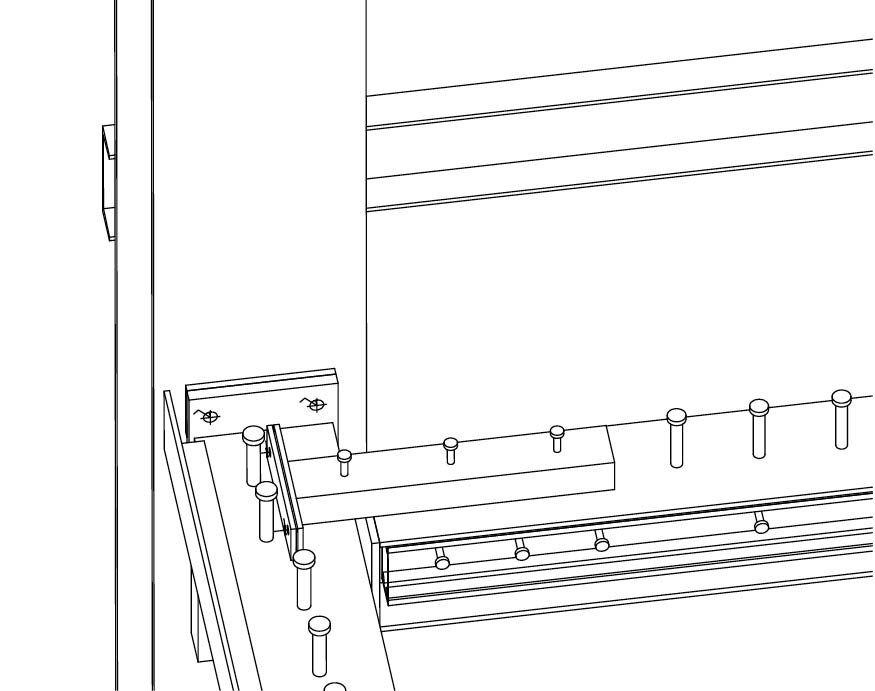

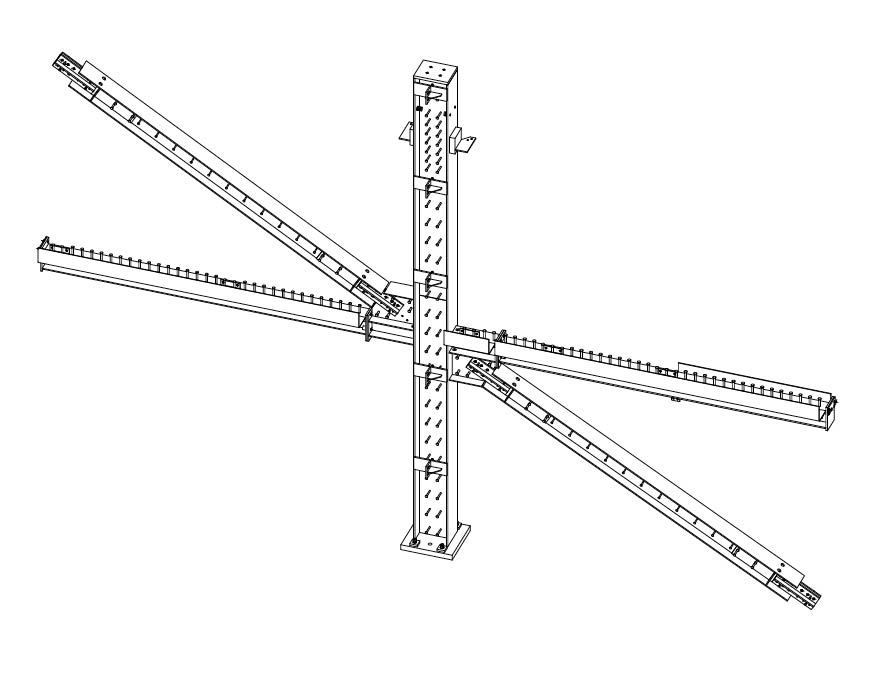

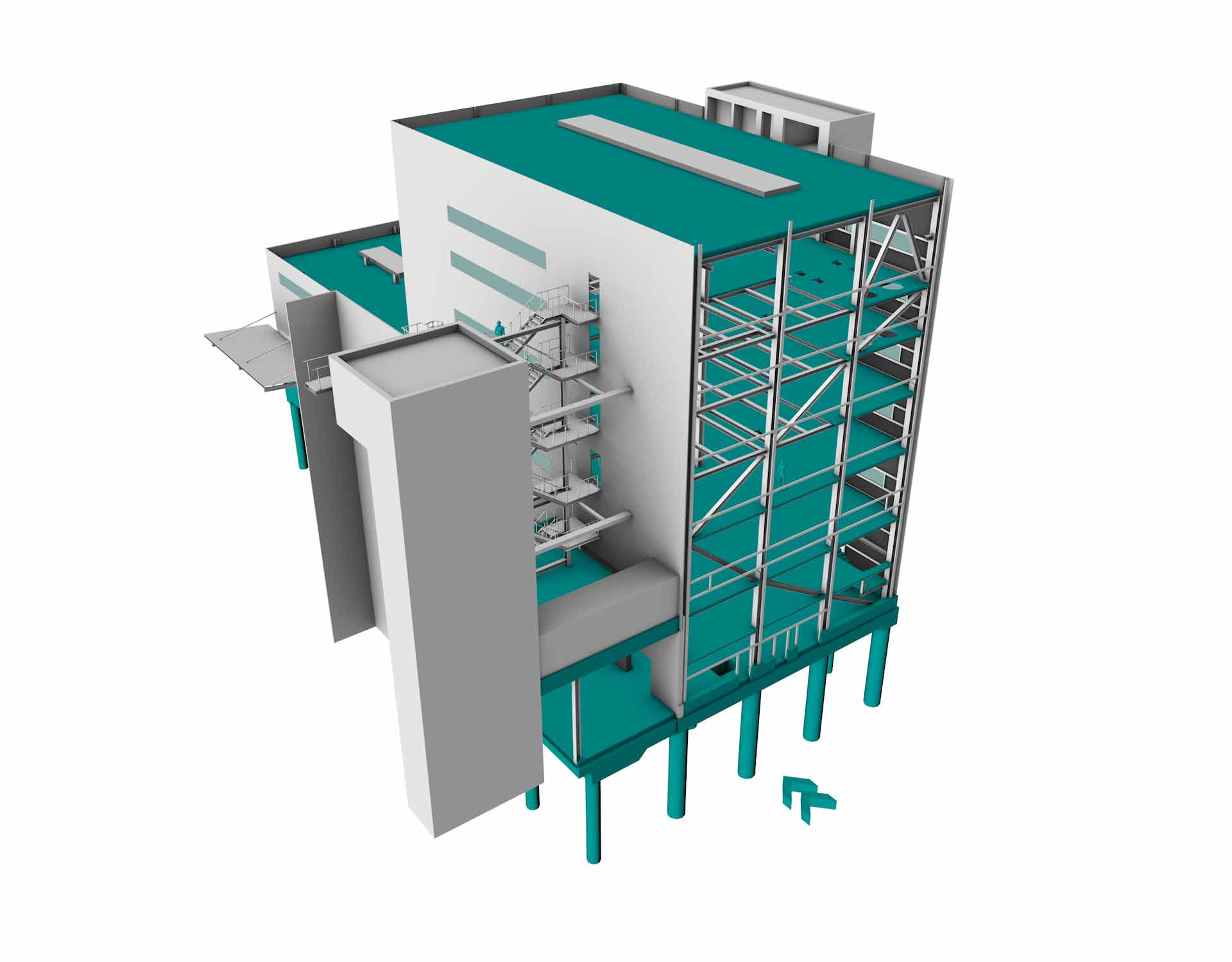

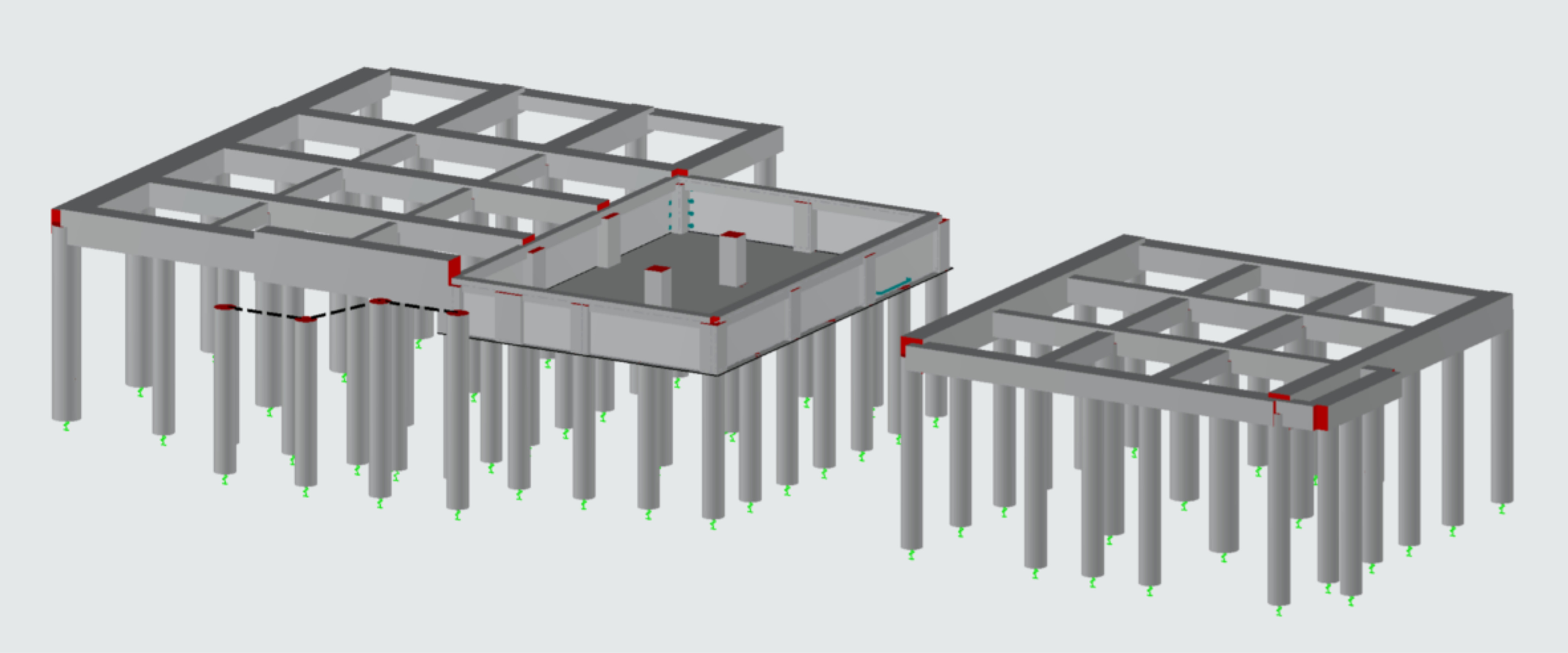

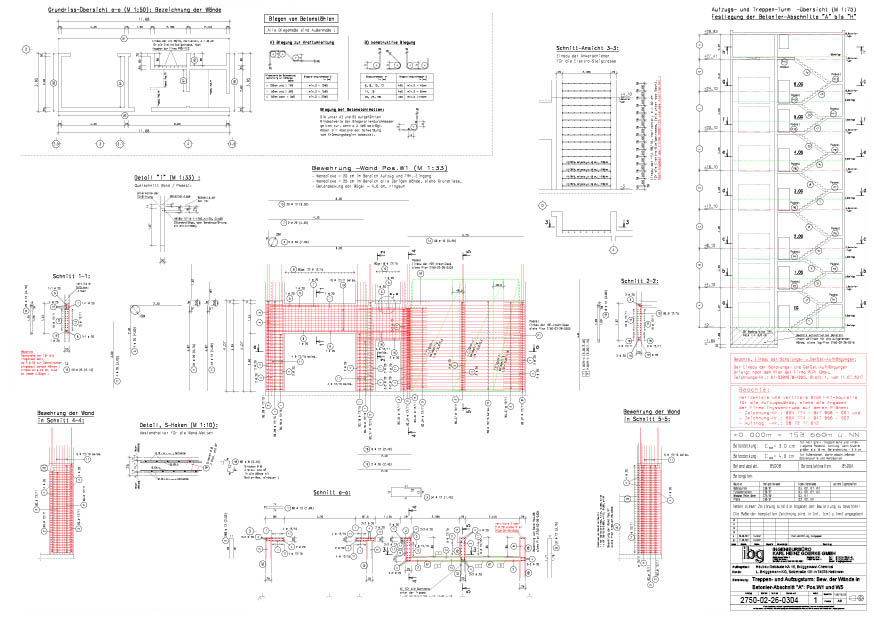

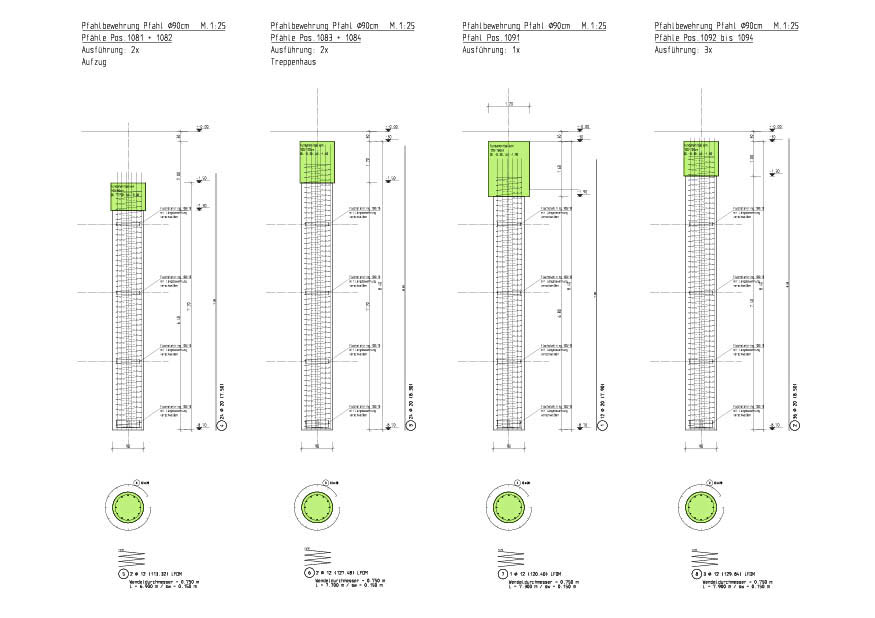

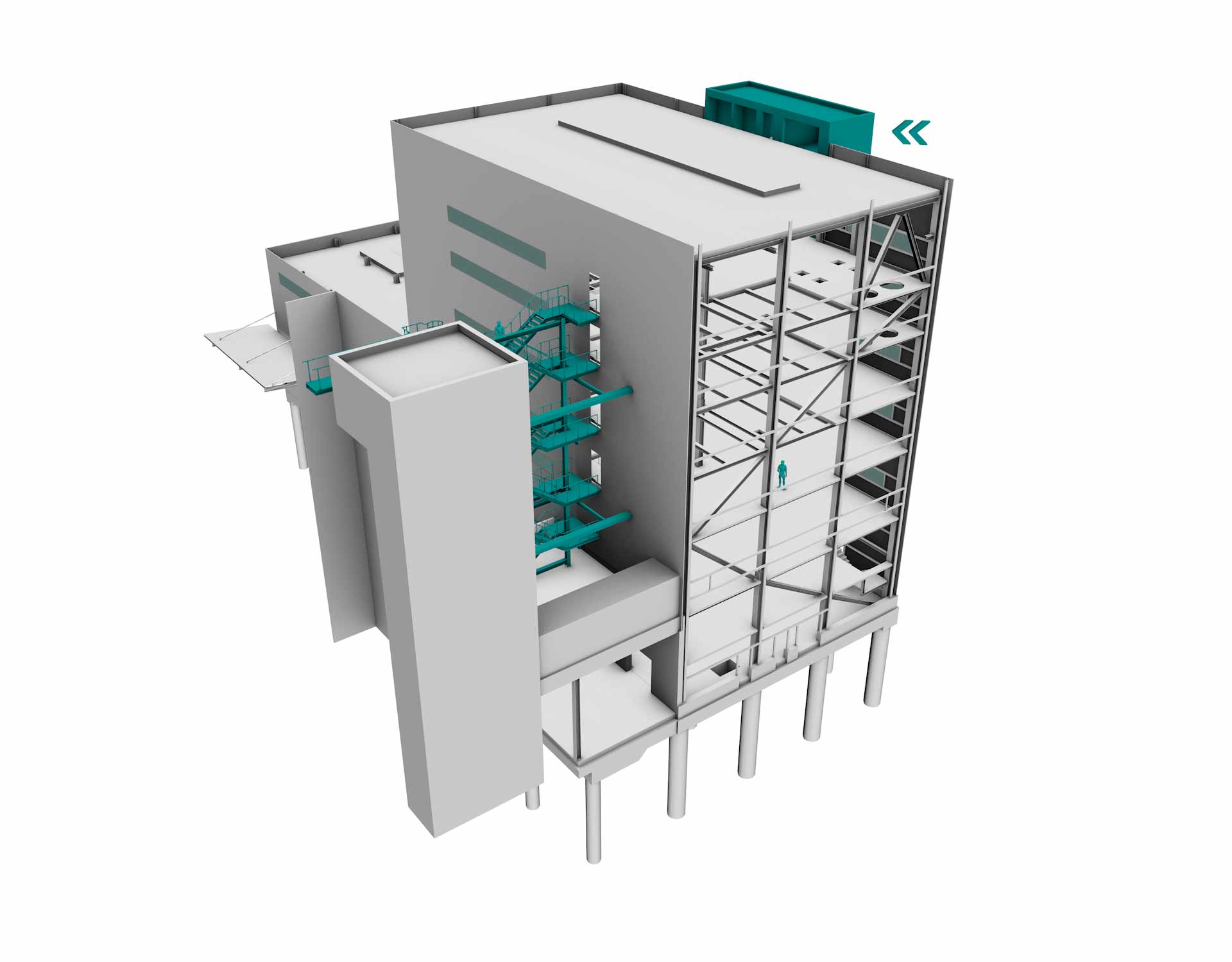

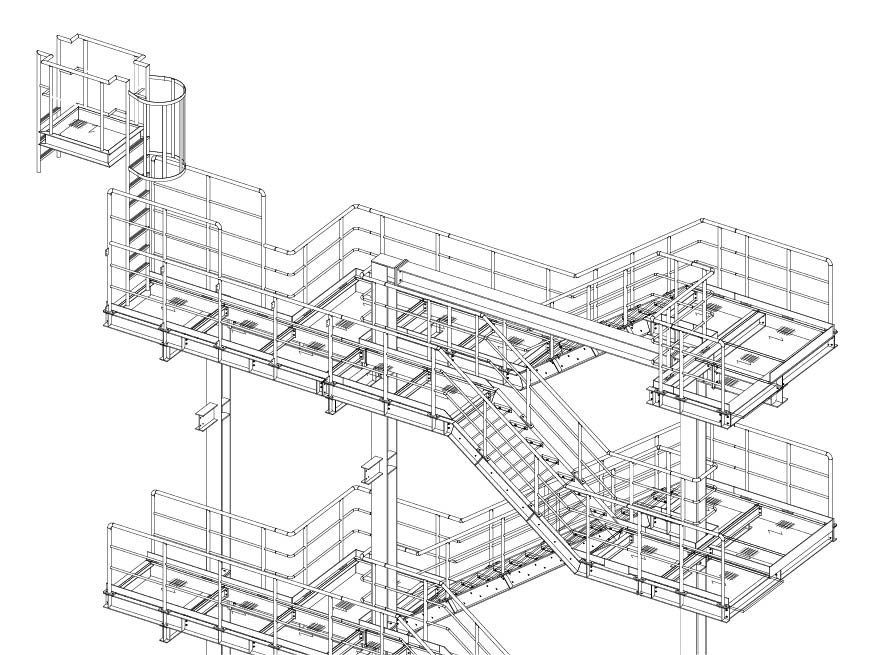

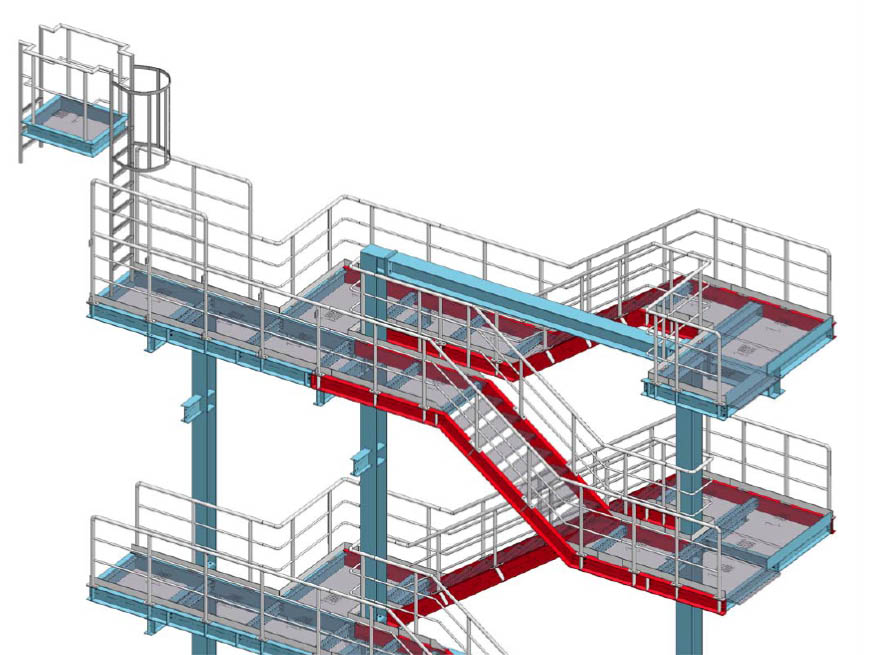

Construction of a new production building and logistics building for the manufacture, packaging and shipping of plastic additives. A fire protection requirement of F90 applies to the entire building. In order to fulfil this requirement, while at the same time assembling quickly with small component dimensions and partly variable interior space, a composite construction was selected for the implementation process. The lift tower and stair tower is structurally separated from the building and was constructed as an in-situ concrete process. The escape stairwells are pure steel constructions. The foundation was carried out with piles at a depth of approx. 10 m into the rock layer.