HUTHMANN ABS / Steel construction

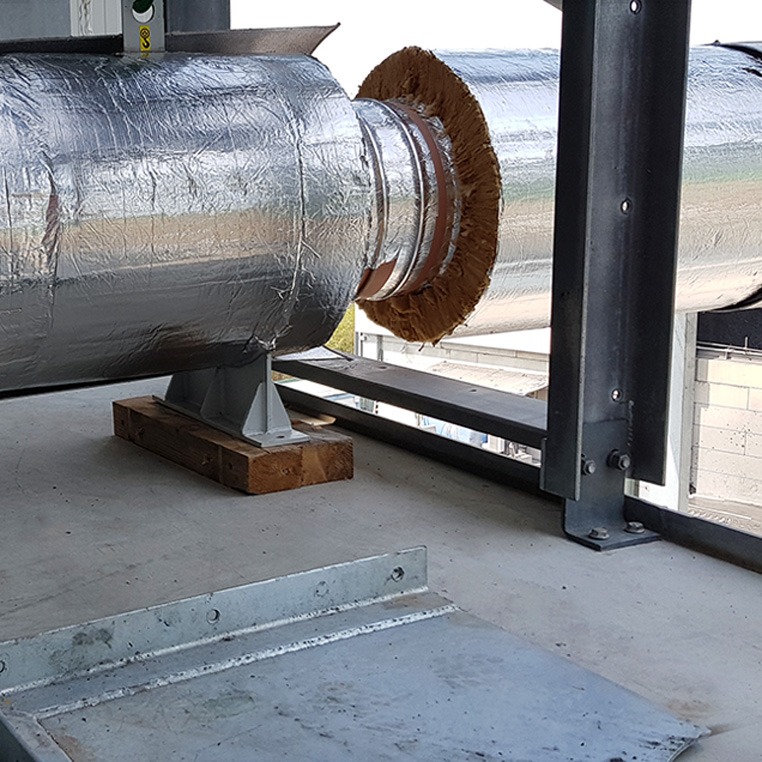

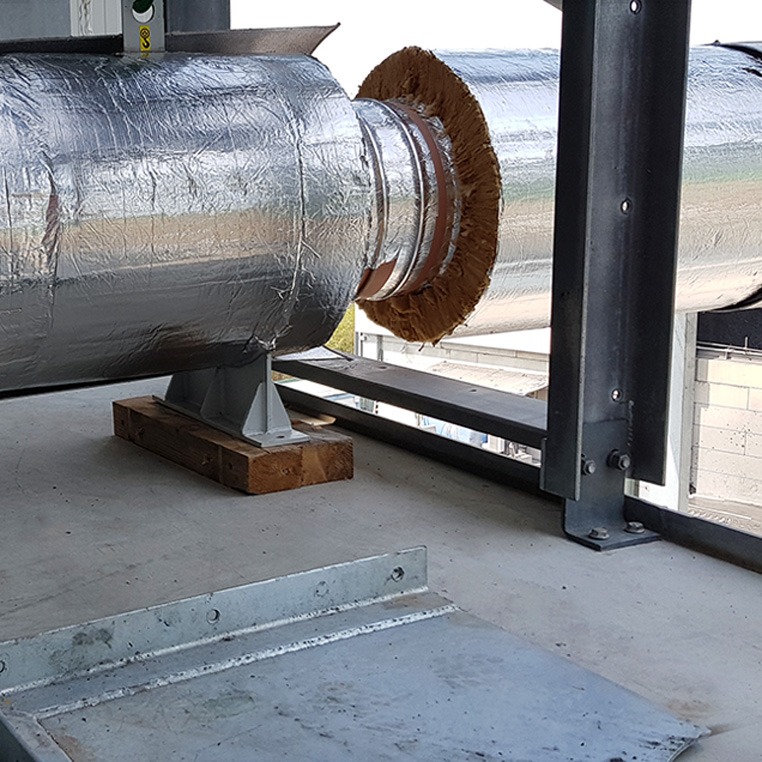

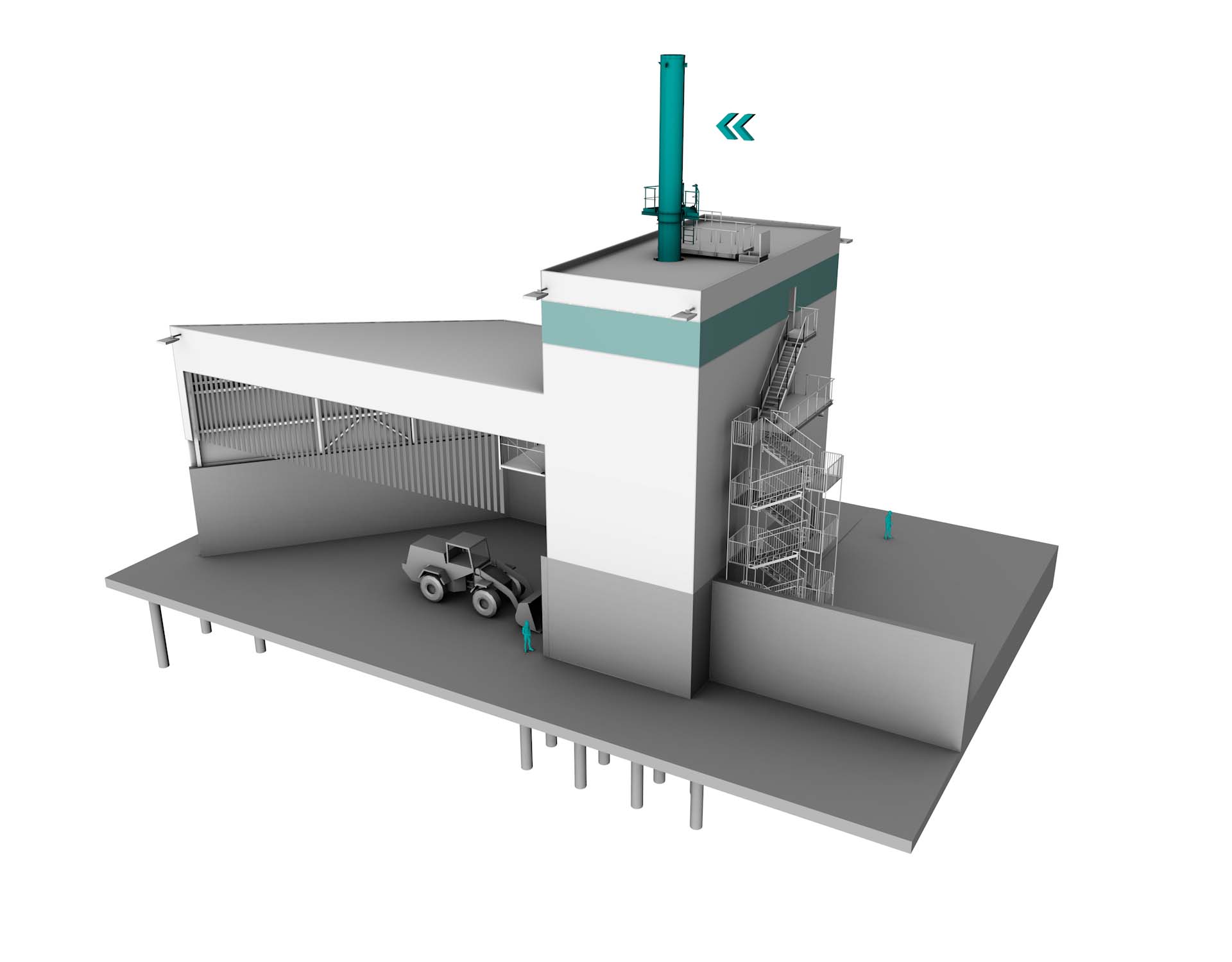

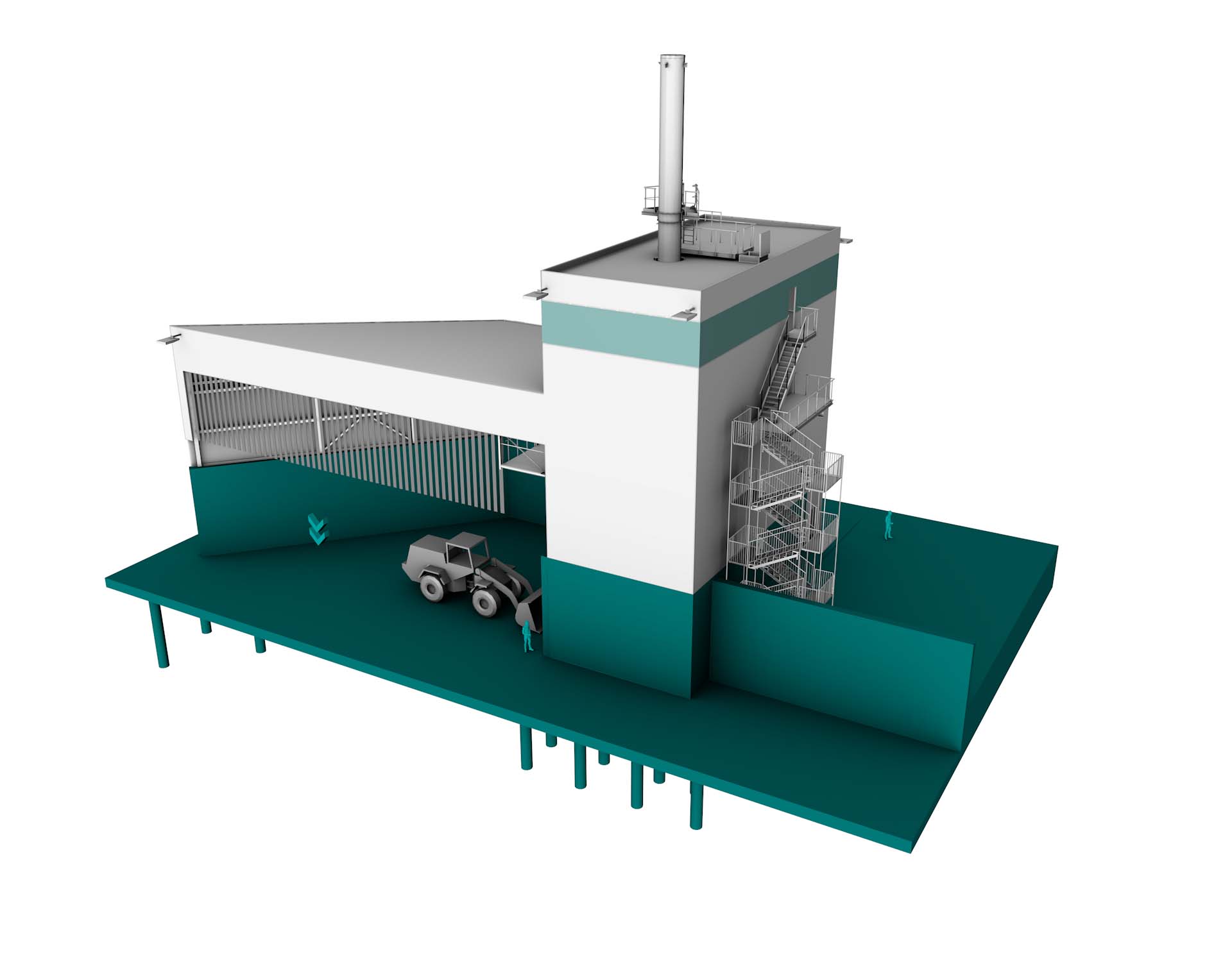

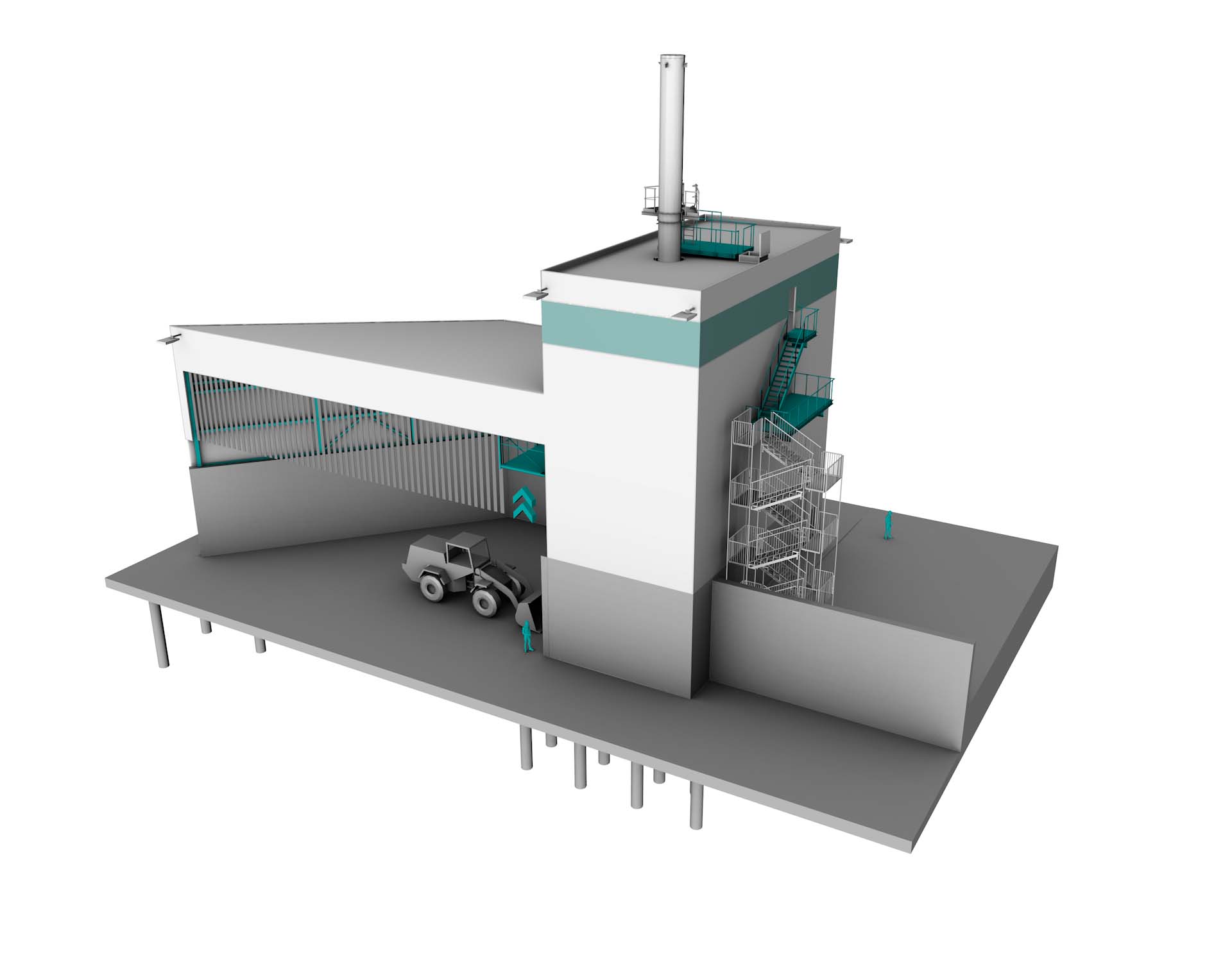

Plant for the delivery and treatment of slag and dust for additional processing as filling material. Tipping out hall and treatment sluice with extraction plant for generating negative pressure.

SAFETY AND ENVIRONMENTAL PROTECTION

ASPECT 1

Safety and environmental protection

When materials are tipped out, dust is generated which must not escape from the building in an uncontrolled manner. Utilising an efficient extraction system, combined with the installation of an elaborate internal cladding for the walls, enables the dust to be extracted in a controlled manner and bound in a filter system. This therefore ensures a high level of personal and environmental protection.

DETAILS

IN DETAIL

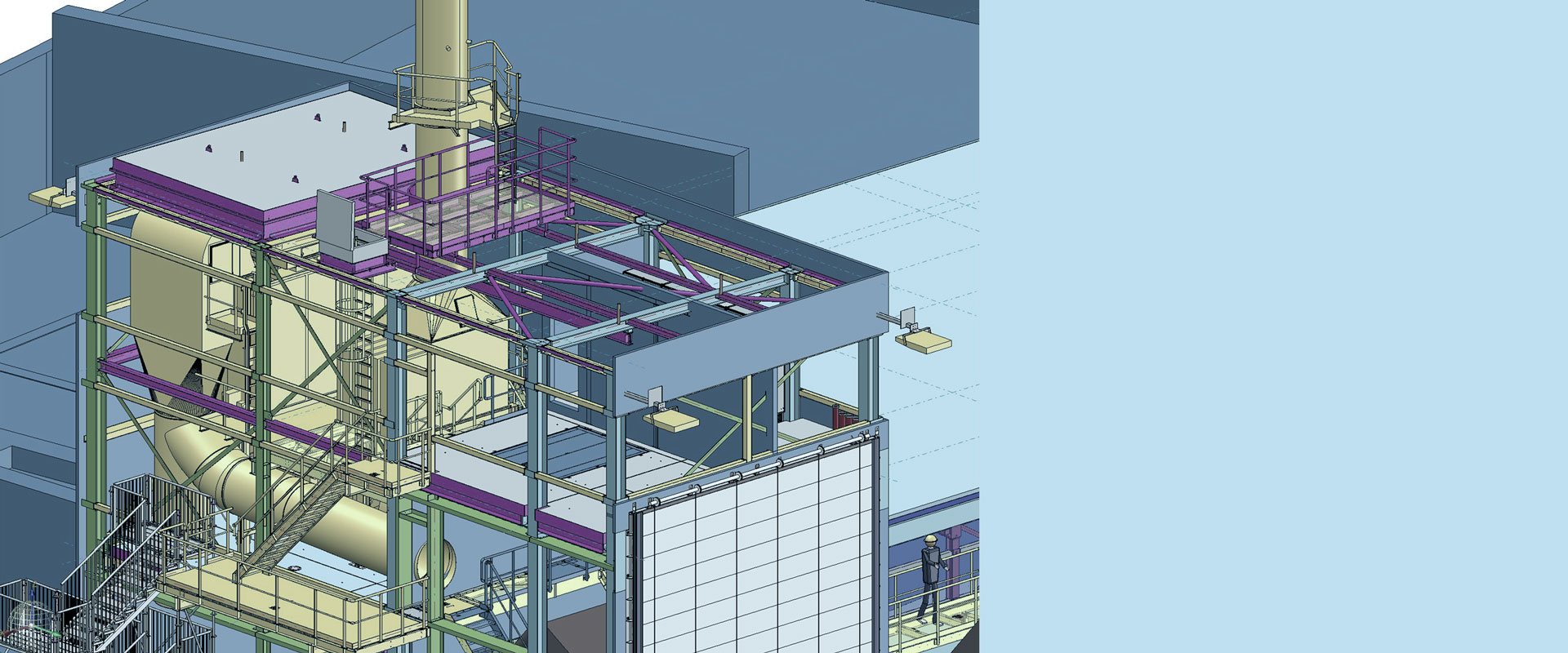

EFFICIENT COMBINATION OF REINFORCED CONCRETE AND STEEL STRUCTURE

ASPECT 2

Efficient combination of reinforced concrete and steel structure

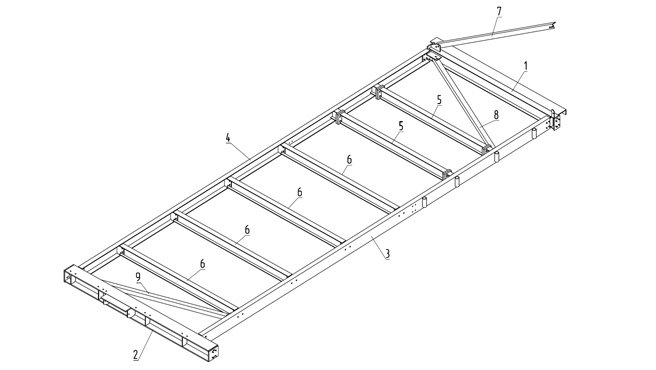

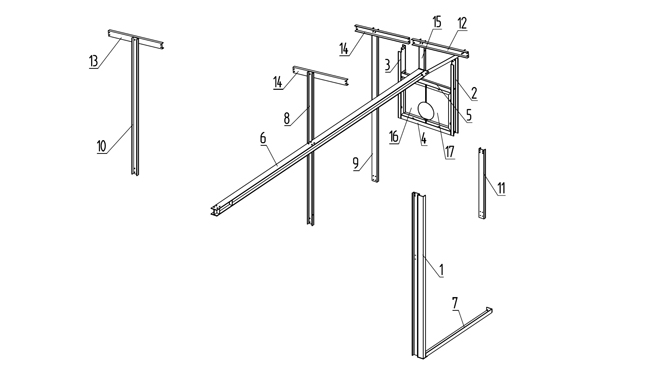

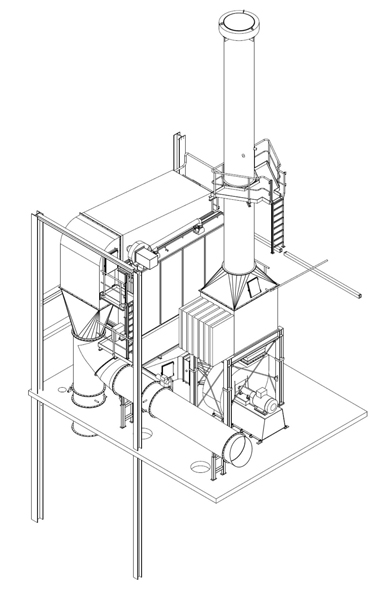

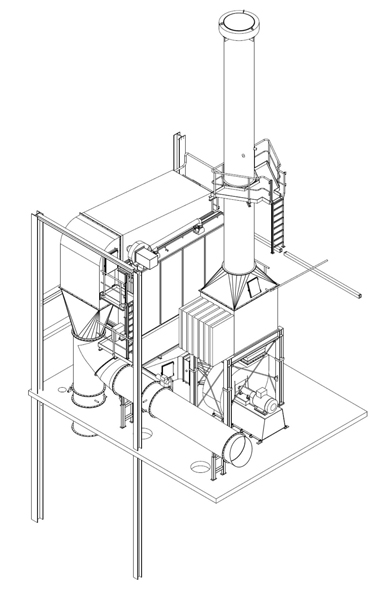

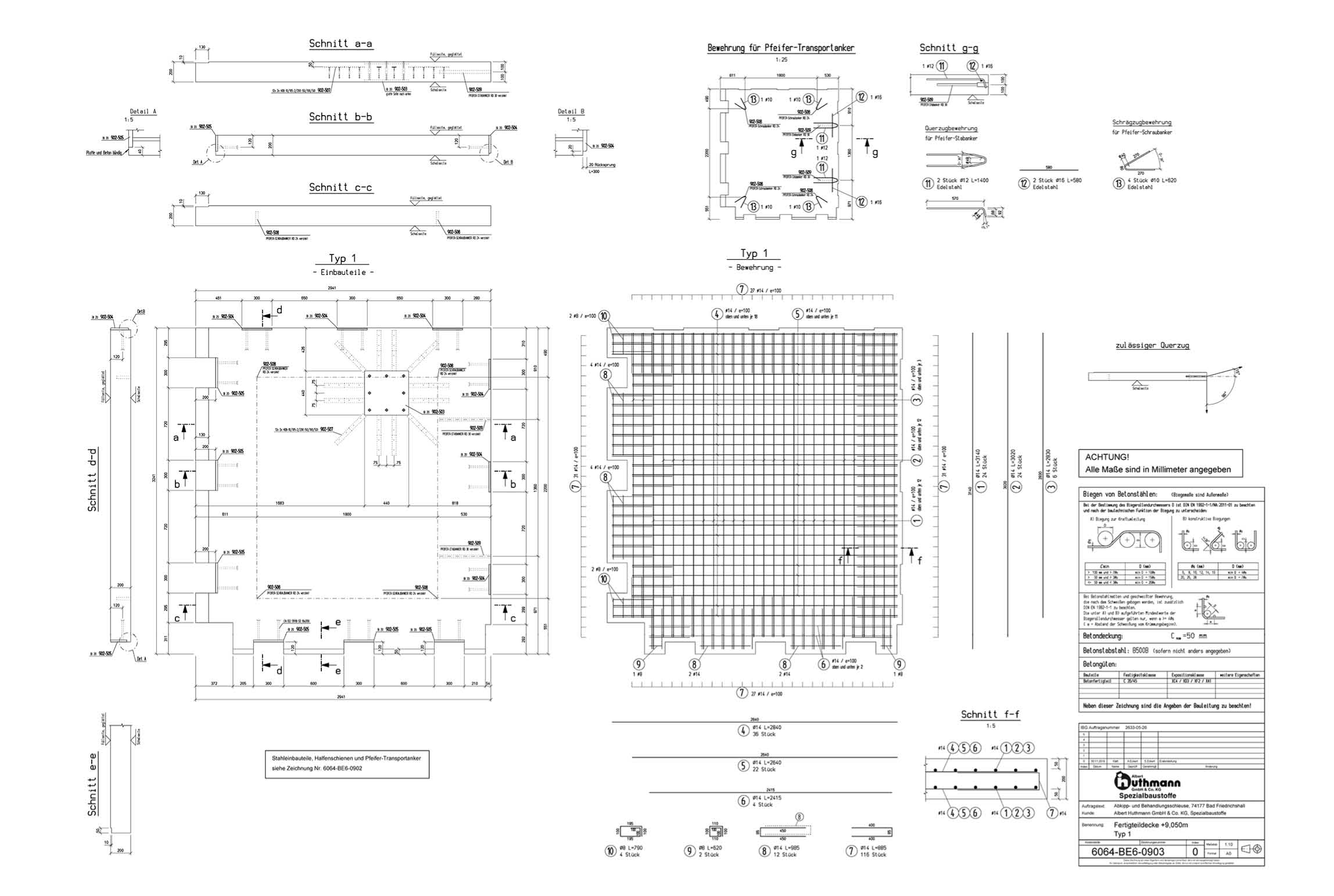

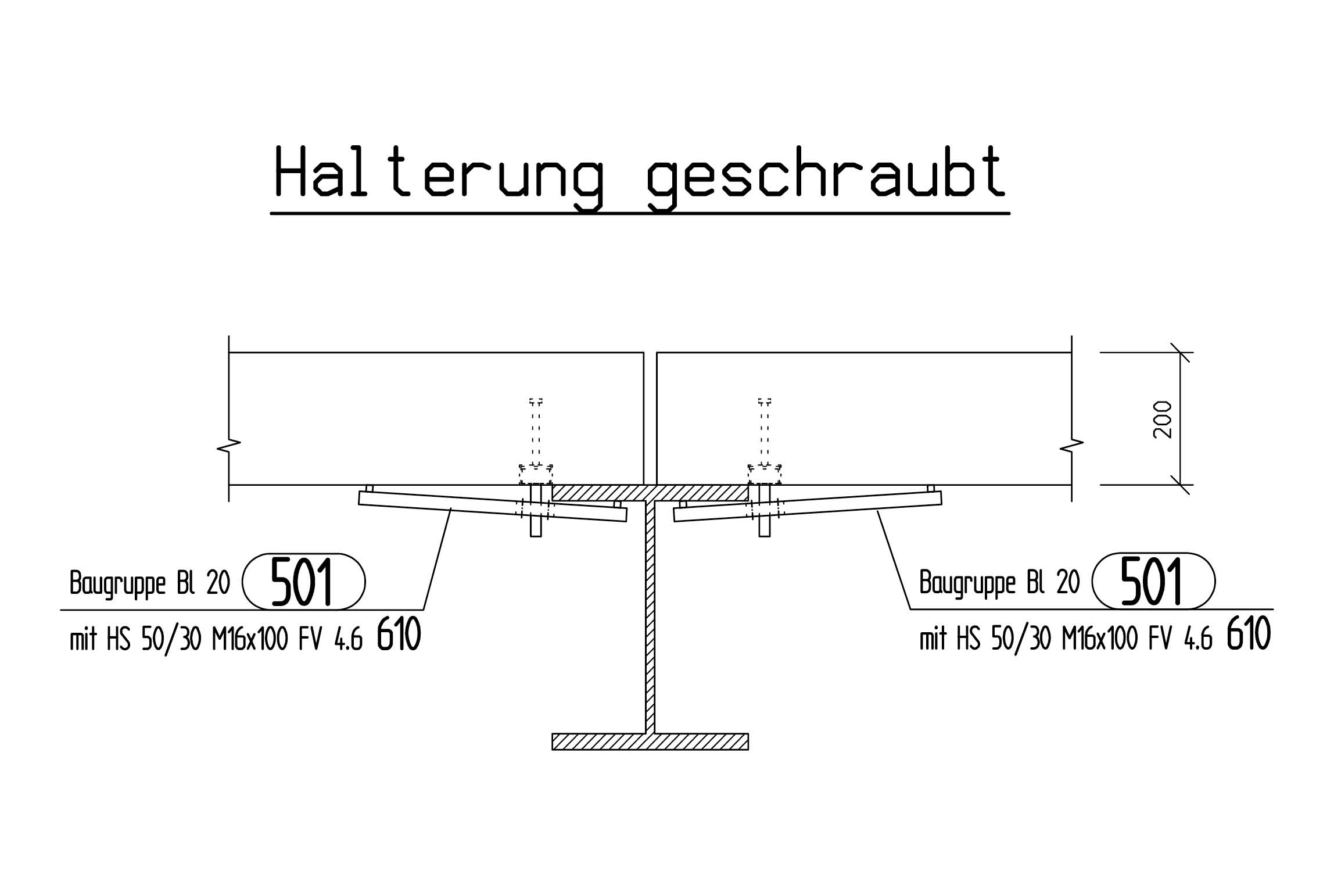

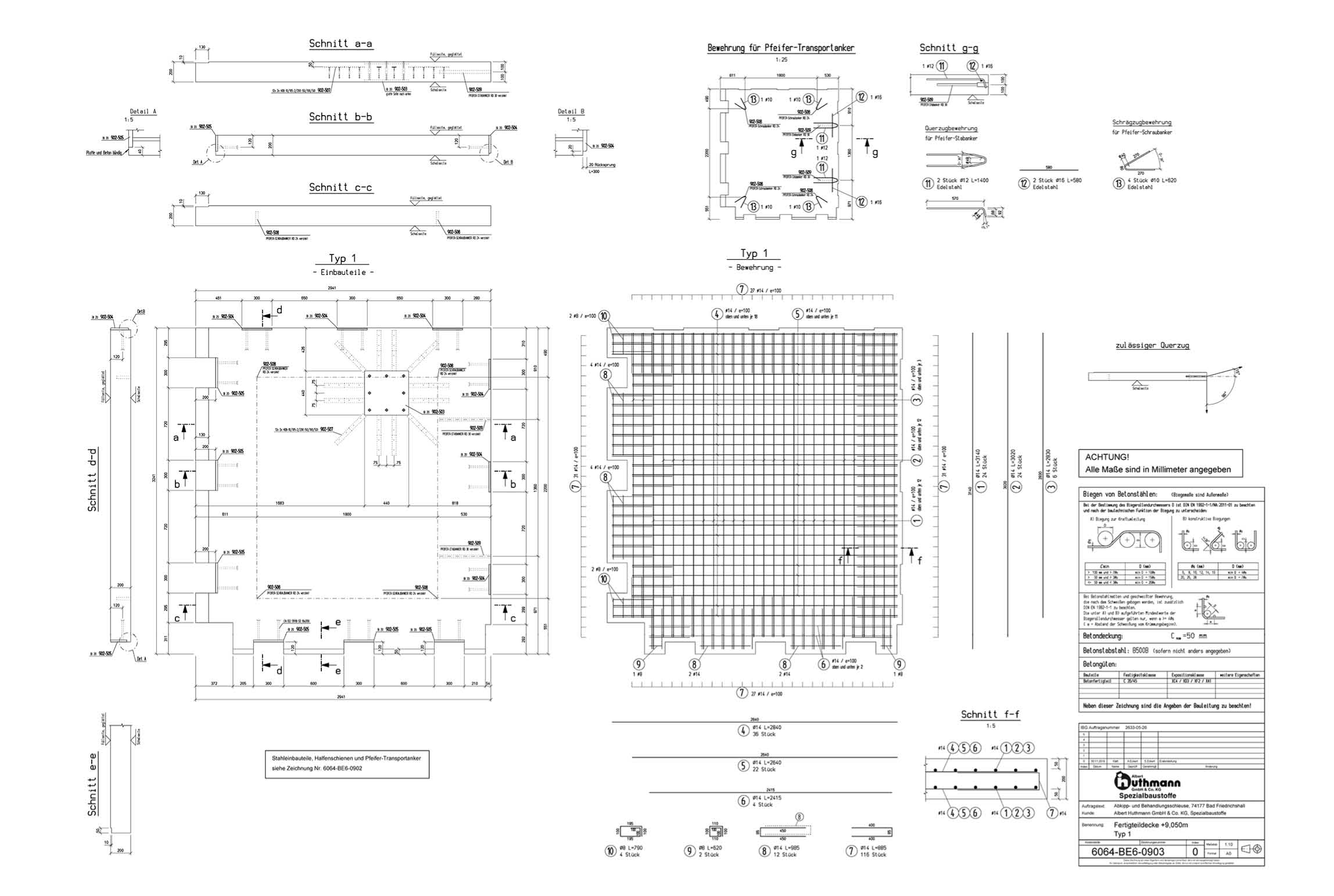

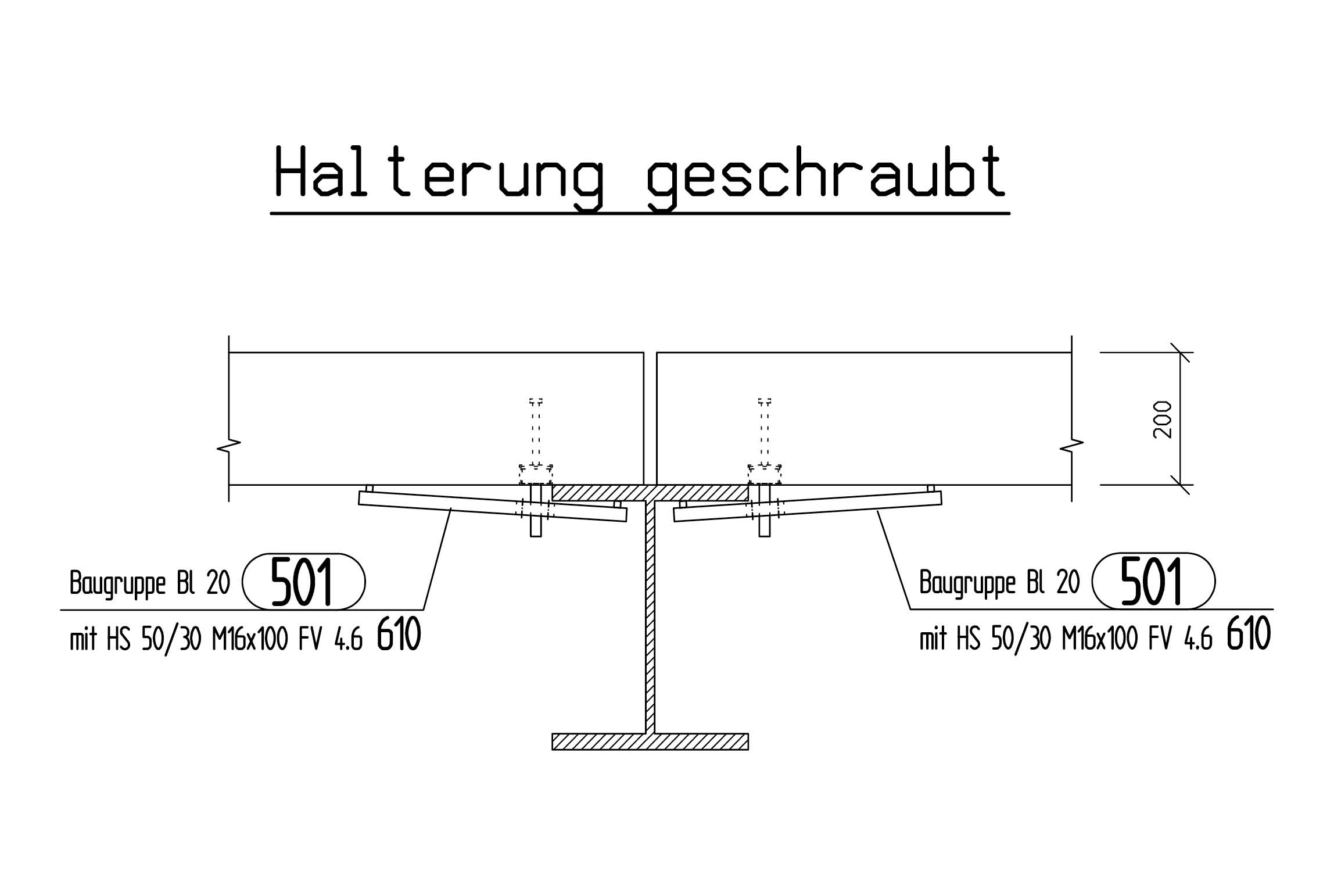

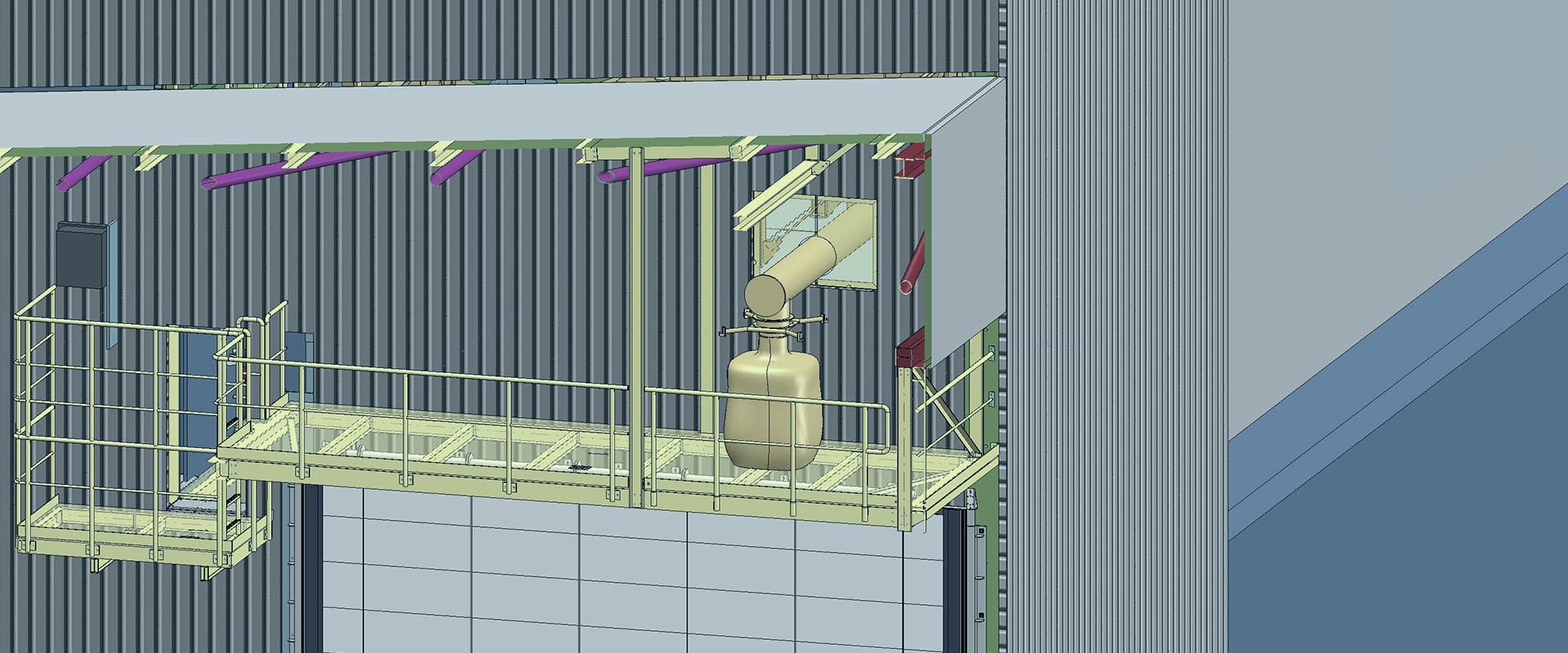

The sensible combination of reinforced concrete and steel construction enables you to experience all the benefits that each respective method provides. Highly load-bearing prefabricated concrete slabs are utilised in the area of installation sites for machinery whose type and exact position will only be determined later. The mass of the concrete slabs dampens the vibrations of the machinery. Furthermore, it is ensured that the machinery loads are safely transferred to the steel girders of the framework, regardless of their exact position. Control, inspection and maintenance access points are constructed in a steel construction with grating and bulb sheet metal coverings and can also be placed on the concrete slabs after installation of the machinery technology.

DETAILS

IN DETAIL

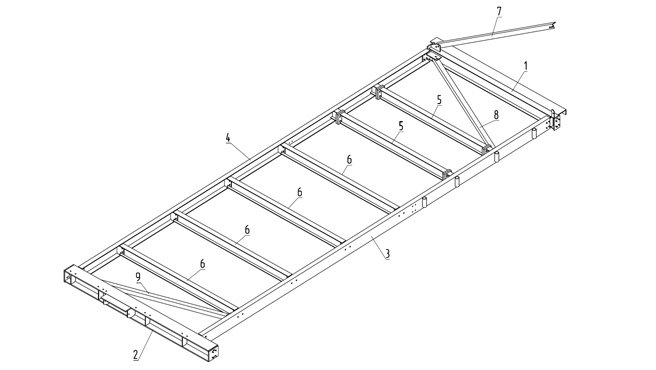

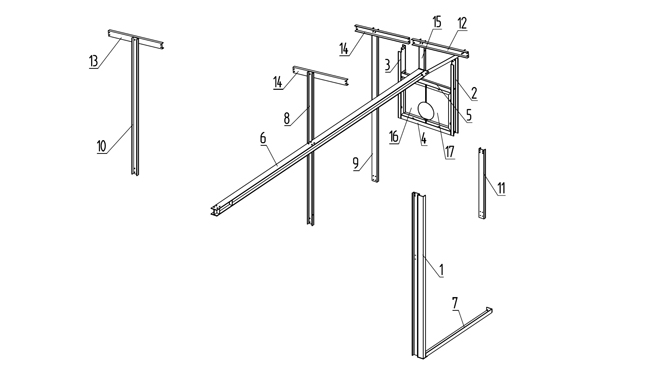

OPTIMUM ADAPTATION OF THE DESIGN TO THE MACHINERY INSTALLATION POSITIONS

ASPECT 3

Optimum adaptation of the design to the machinery installation positions

With a steel construction, one is always able to respond optimally to the requirements of the machine plant. Access routes for service measures and supports for plant components can be easily implemented. Even wall claddings with substructures and entire girder layers can be adapted to amendments in the machinery installation positions during the planning stage and, in some cases, even during the execution stage.

DETAILS

IN DETAIL